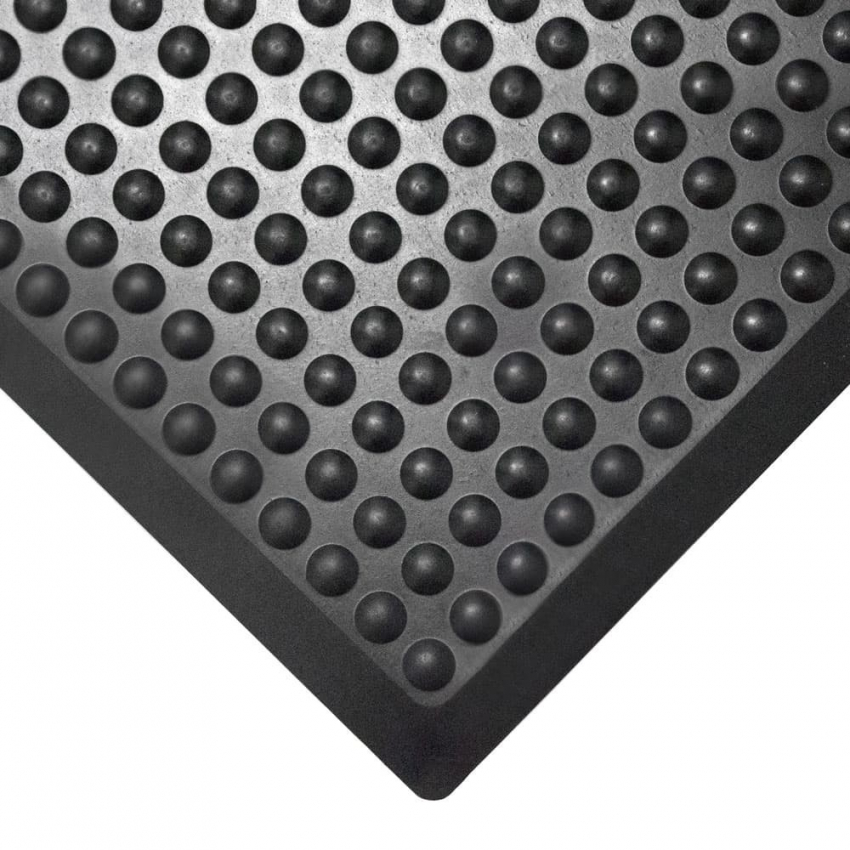

Aesthetic" anti-fatigue mat withergonomic bubble surface. This mat features a raised surface that stimulates blood circulation in the lower limbs through micro-movements. What's more, it absorbs footsteps, considerably improving comfort for professionals working in static standing positions.

- Available in two versions: natural rubber or nitrile

- Modular system for installation on large surfaces

- Nitrile version ensures resistance to oils and chemicals

Available in two sizes or in modular systems

Cleaning: Use a high-pressure hose (not exceeding 60 psi) to remove dirt and debris from the mat. For best results, use a mild detergent to clean. Do not use steam, degreasing agents or caustic chemicals. Do not mechanically scrub mats.

*Not resistant to greasy products and mineral oils.

Ideal for manufacturing production areas where employees stand in static positions.

Individual components snap together to cover any length required, or finish individual mats with bevelled edge all along.

| BF010003 |

Data sheet

| Format | Slabs |

| Surface | Bubbles |

| Properties | Anti-fatigue |

| Composition | |

| Thickness | 14 mm |

| Weight | |

| Resistant to chemicals | Yes |

| Environment | Dry environments |

| Operating temperature | |

| Intensity of use | Intense |

| Wear index | 2/3 (Very good) |

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.