Antistatic floor covering limits the risk of electrostatic discharge and protects sensitive equipment and personnel. Evacuates static electricity accumulated either by surrounding equipment or objects, or by users. Improves worker comfort and reduces the various risks associated with static standing posture (lower limb and lower back pain).

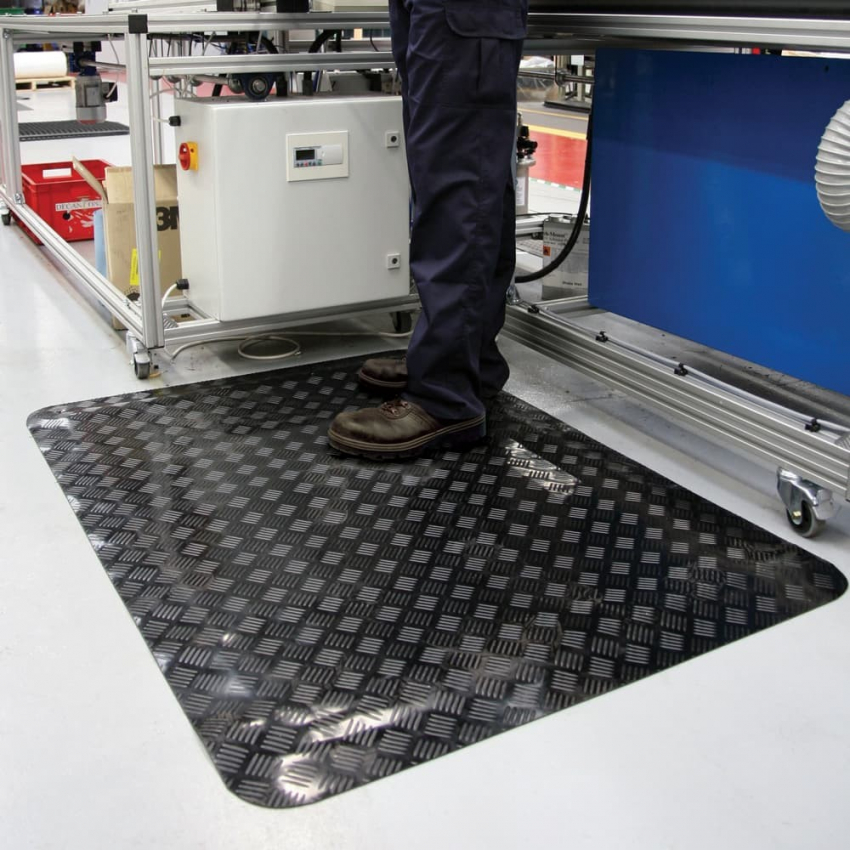

This mat cushions footsteps and enables micro-movements that help limit RSI (musculoskeletal disorders). Manufactured for intensive use in a dry environment, this mat resists oils and increases safety thanks to its bevelled edges.

Available by the linear meter and made-to-measure.

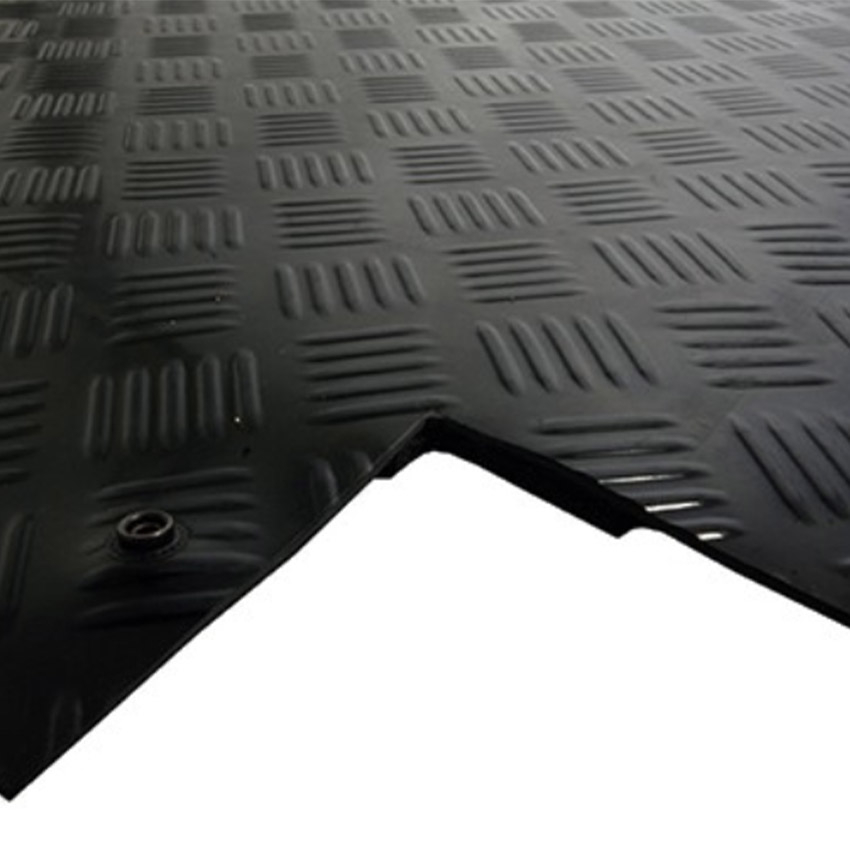

Composition: EPDM foam bottom layer with anti-fatigue properties. Top layer made of a blend of nitrile rubber and NBR / SBR which effectively reduces the risk of slipping.

Good resistance to petrol (also suitable for unleaded petrol): 70 h, 23°C, fuel B (ISO 1817), 20% volume swelling for minor mechanical requirements.

| SENSODIAL |

Data sheet

| Format | Roller |

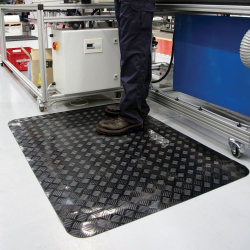

| Surface | Full |

| Design | Sheet metal |

| Location | Interior |

| Properties | Anti-fatigue ESD / AS |

| Thickness | 10 mm |

| Maintenance / Cleaning | Brushing / Washing / Vacuuming / Pressure washing (max 60 psi) - only mild detergent |

| Environment | Dry environments |

| Operating temperature | up to 70°C |

| Intensity of use | Very intense |

| Wear index | 3/3 (Excellent) |

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.