If there's one sector where hygiene regulations must be followed to the letter, it's the food industry. Even if, in other sectors, cleanliness remains a central pillar that plays a role in the smooth running of the business. Failure to comply with regulations can be punishable if they are not applied and respected. Indeed, it's one thing to be aware that maintaining hygiene is an obligation to ensure consumer protection, but it's quite another to apply it within the various production lines.

We know how important hygiene is, which is why we offer customized solutions to suit every situation. Here, NEOSOL explains why cleaning and disinfecting food processing plants is vital.

Cleaning food processing plants: the regulations

The "hygiene package" is the name of the sanitary protocol that all manufacturers must respect to ensure hygiene on their premises. Since this European regulation came into force on January 1, 2006, numerous standards have been introduced. These standards guarantee the cleanliness of the different areas of a factory: production, packaging, raw material and finished product storage, delivery, checkroom, etc.

This legislation has its origins in the Commission 's White Paper on Food Safety, which was prompted by numerous health crises due to a lack of cleanliness in industry.

Whether it's the disinfection of machines, the cleaning of floors or the cleanliness of employees' clothing, hygiene must be a priority. Numerous inspections are carried out every year to ensure that standards are respected, and that hygiene objectives set by regulations are maintained. A maintenance logbook must be kept to guarantee transparency and traceability of hygiene. That's why it's vital that every employee is trained and informed about the health risks associated with their workstation, as well as the various protocols for cleaning and disinfecting machines and other equipment.

The 5 regulations of the hygiene package are :

-

- EU Regulation 2017/25: concerns the control of cleanliness by food hygiene and health organizations.

-

- EC regulation n°178/2002: makes foodstuffs available on the market, defines traceability and the withdrawal of products likely to present a health risk.

-

- EC regulation n°852/2004: implementation of processes based on HACCP principles - ISO 22000 standard: management of food safety using the HACCP method.

-

- Regulation (EC) n°853/2004: lays down specific rules for the hygiene of foodstuffs of animal origin.

- Regulation (EC) n°183/2005: establishes food hygiene requirements.

These regulations include a number of measures, such as

- Ventilation adapted to each area and easily accessible for replacing air filters,

- Providing employees with all the necessary equipment to facilitate the maintenance of their workstations,

- The obligation to use drinking water for cleaning and disinfection,

- Installation of insect screens when windows are open,

- Install a room for storing cleaning materials and products,

- Installation of suitable flooring,

- Protocol for cleaning machines, equipment and hands,

- Etc.

Hygiene compliance in the food industry with NEOSOL's food industry mats

As you can see, compliance with hygiene rules and regulations must be your top priority, and NEOSOL understands this. That's why we offer you solutions adapted to each area and workstation.

We have developed a range of food-processing mats that respond to the problems encountered in this sector. These hygienic mats have been designed with antimicrobial rubber to stop the proliferation of bacteria. They form a barrier between external dirt and internal cleanliness. They also have the advantage of being highly resistant, anti-slip and anti-fatigue.

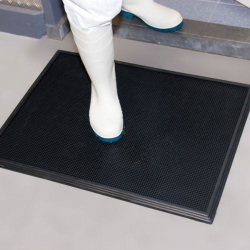

There are also mats specially designed to disinfect the soles of shoes. This is the case for the disinfecting entrance mat. It cleans shoes while disinfecting them. Extremely useful in areas where maximum hygiene is required.

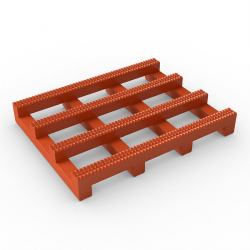

Other useful floor coverings include hygienic gratings, mats for catering kitchens, mats for damp or oily environments.

![Fire classification, UPEC and ISO 10874 standards Fire classification, UPEC and ISO 10874 standards]() Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More

Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More![Static electricity risks and solutions Static electricity risks and solutions]() Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More

Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More![Professional mats: how to care for them? Professional mats: how to care for them?]() Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More

Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More![Accessibility and ERP: how do I know if I'm in compliance? Accessibility and ERP: how do I know if I'm in compliance?]() Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Leave a comment